|

CSY |

|

|

Home Page |

||

|

CSY Workshop Home |

||

|

Soggy Paws CSY Home |

||

|

New Cat Workshop Pages |

||

|

Engine |

||

|

Electrical Systems |

||

|

Plumbing

Systems |

||

|

Refrigeration |

||

|

Rig

& Sails |

||

|

Hull |

||

|

Cockpit |

||

|

Deck |

||

|

Interior |

||

|

Steering |

||

|

Electronics |

||

|

Computers |

||

|

Workshop Links |

||

|

Miscellaneous |

||

|

About Us |

||

|

Contact Us |

||

|

About CSY Boats |

||

|

See more 'boat project' discussions by Dave on the CSY Owners Forum |

Last updated:

05/14/2023

Future Additions:

Cutlass Bearing Installation

Bow Eye

Dynaplate

(27 Dec 08 CSYO Post) For starters if you

have time do a search on the Topica site on keel length. There has been some

posts on this subject in the past. The designer, Peter Schmitt told me

personally a year ago that there is very little difference in upwind

performance between the two keels and no stability problems with the short

keel version. I suspect it is more like 5 degrees of leeway more for the

short keel.

There are other advantages/disadvantages which I can post to you later. We

are commencing a circumnavigation now with a short keel tall rig and I have

sailed our boat around the Carib and up and down the Keys many times. We

don't have any problem with our boat's upwind ability especially since we

have a well tuned rig and new sails. I believe that those two things will

make more difference in upwind ability than the 18" of keel length. Of more

concern is where you may cruise in the future and whether or not you can get

into the places you want to.

I have considered "capping the keel" with a plate on the bottom to direct

the water flow along the keel rather than have it fall off the bottom and

cause turbulence drag but haven't gotten around to that yet. 20 years ago I

talked to Ted Brewer about this and he seemed to think that it would be a

worthwhile project on a new shallow draft boat build. I think that it would

help upwind performance some on a CSY.

The shallow draft models from the factory were supposed to have 2000# added

to their keels to offset the weight of the deeper keels. I haven't noticed

any stability problem with our boat, but if you were concerned you could

always add lead, and you would want to do this if you cut off a keel.

(8 May 09 CSYO Post) Re cut keels: according to the CSY manual the concrete

was first poured into the empty keel and then covered by an upper fiberglass

keel bottom 18" up. So, once you identify where the upper keel bottom is, it

is relatively easy to cut the fiberglass just below this around the outer

perimeter of the keel with a circular saw. Since there is no mechanical

connection of the concrete to the fiberglass the lower portion of the keel

will then drop off. From there it is a simple matter to dress up the edges

and paint after applying a barrier coat.

I have heard of several cut keels and seen one done by a friend in Key West.

It was done in a day by just blocking the boat up and cutting a half inch or

so below the upper fiberglass bottom. Since the concrete is not physically

attached to the fiberglass, when the outer fiberglass is cut the fiberglass

encased concrete keel falls off. All cut keels that I know of were done to

44 walkovers. If you are interested in looking at a cut off keel, I believe

that Steve Silverman has one.

To answer your question how to identify a cut keel, I would look for a keel

bottom with sharp edges and maybe no gelcoat on the bottom. Factory keel

bottoms have a thick layer of gel coat and are fairly flat, while a cut keel

bottom might show raw fiberglas, no gel coat and maybe an imbedded concrete

pattern. Also, the loss of keel weight might have been offset by a

knowledgeable owner with additional lead ballast placed in the

bilges-something you could see.

If you are still looking for a project boat you might consider, Pacifico now

in the Rio Dulce for sale at $55K. It was a bit rough and needed work, but

was being used for cruising in the Carib. We were next to them on the Rio at

a marina for a few months a year ago. What boat are you looking at now?

(9 May 09 CSYO Post) We all know that the keel does 3 major things for a

boat underway: improves stability by adding weight below the center of

gravity, provides lift because of its foil shape and improves lateral

resistance because of its surface area. Those are all plusses for a deep

keel. The question is how much of a plus. According to Peter Schmitt, our

designer, when I asked him that question directly, not much. With a little

time someone could probably come up with the calculations to analyze the

differences. And maybe there is someone reading this forum that can provide

an accurate analysis based on actual experience with both hulls. But even

that would be hard to evaluate because of the differences between any two

like boats' sails, rig tuning, bottom condition, etc.

On the negative side are the significant issues of 19" of increased draft

(as you know a real problem getting into the Rio Dulce, and elsewhere),

increased wetted surface area and reduced slippage down a large storm wave.

Regarding the 6'-6" initial draft and more like 6'-10" or better in cruising

trim, there are many places in the southern US, Bahamas, the Carib and even

Ecuador that are a big problem for a boat with that kind of draft.

So there you have it again, tradeoffs and compromises. I still like my tall

rig shoal draft (now more like 5'-3" in cruising trim) for what we are

doing. My gut feeling is that there isn't that much difference in

performance or stability between the two keels to make me look for one or

the other if I was buying a boat. For us the difference in draft is the real

issue.

Cutting a 44's Keel

(26 Oct 09 CSYO Post) The upper lead keel bottom should be almost exactly

18" above the lower concrete bottom, so you should be very close with your

cut.

Based on my research, I believe the loss of draft is about one inch per 1500

pounds removed for a CSY 44 hull. So you will lose just over 3 inches if you

remove 3200 lbs.

But, "not so fast", you will also lose buoyancy by removing 18" of keel. So,

measure and then calculate the cubic volume of the cutoff keel. Next, figure

out the weight of water that that volume would displace (in saltwater 64 lbs

per cubic foot). Finally, subtract that weight from the 3200 lbs and

recalculate, using the 1" draft loss per each 1500 lbs removed.

If you add about 2000# back into the bilge, as CSY said they did for the

shoal keel models in their manual, you will probably come out about where

you started for the waterline. However, if you plan on going cruising

sometime in the future, you will certainly add several thousand pounds of

cruising stuff to the boat. And topsides paint systems like Awlgrip/Imron/Sterling

bubble when they get wet. So you might as well raise the waterline now

rather than later. We are currently up about 4" from our original waterline

and I have eliminated the boot stripe.

Boat Lettering

We just ordered new vinyl lettering for Soggy

Paws online... it was fast, easy, and surprisingly cheap. Our 8" x 53" boat

name in custom font, custom colors, was only $35. We used

Speedy Signs. They

have a really neat 'create your lettering' tool online. You can do simple

boat lettering, or get really creative and use their 'vinyl design tool' and

add graphics.

Interestingly, we wanted to add a little 'graphic' to our name... some cat's

paws. We found if we used their custom graphic tool, and made the boat name

and the paws (as shown below), it would cost $75. That's a lot of extra

money for 6" of paws. So we broke it up into 2 items... just the text, and

just the graphic. A little more work on our part, but it brought the price

down to $50.

So if it's time to spruce up your boat an renew your lettering... go for it!

Removing the old vinyl lettering is really easy... a little heat from a hair

dryer, and a little adhesive remover, and a plastic scraper, and you can

have brand new lettering in about an hour.

You don't need a professional to apply the vinyl letters. Speedy Signs has a

pretty clear 'how to' instruction sheet, and will also sell you an

'application kit'. (but you don't need their fancy kit, a little soapy water

works just fine).

44 Hull Pounds per Inch Immersion

5 Nov 09 CSY Post. For those of you that have the 44 hull and have

been wondering just how much weight/junk you have added to your boat over

the years here's some good news. I recently met Gram, a bright young naval

architect (NA), who used to work with the Pedrick Yacht Design Group but now

is heading out into the Pacific with his family aboard the custom Chuck

Paine 62, Visions of Johanna. I asked him if he could help me figure out

just how much weight I had added to the boat based on raising my waterline 4

inches. He offered to help answer this question.

The term Pounds per Inch Immersion (PPI) is a smaller version of Tons per

Inch Immersion (TPI) used in salvage work to determine how hard a ship is

aground. If you know the TPI for a ship and how far (in inches) out of the

water a ship aground is from its normal afloat condition, you can calculate

how much weight must be removed to float it again. That's not normally our

problem. Determining how much extra weight we have aboard, what the boat

really weighs and where the new waterline should be, is.

So, by looking at a lines drawing of the hull which is on the Hull Layup

Plan, we can determine the distance from the centerline to the hull at each

2' station along the length. By plotting this on graph paper, using a scale

of 1 block equals 1', we can get a pretty close approximation of the outline

of the hull at the design water line (DWL). Then, if we count the squares we

can get the square footage inscribed by the hull outline. Since we all know

that a cubic foot of seawater weighs 64 pounds, a one square foot slice 1"

thick will weigh 1/12 of that, or 5-1/3 pounds. Multiply the square footage

by 5-1/3 pounds and you get PPI, the amount of weight it takes to sink your

boat 1" at the DWL.

Fortunately, we don't have to go through all this because Gram did the

calculation using an Excel spreadsheet and some "secret NA math" and came

out with 1513 pounds. But, if you look carefully at the lines drawing, you

will notice that the hull gets slightly further away from the centerline as

you go up the hull. That means that the further the boat goes down in the

water, the more weight it takes to sink it 1". You will have to do that

calculation yourself.

So there you have it, another little known fact about our great 44s.

Hopefully, it will be of use to someone other than myself.

Lightning Grounding Bar

On Soggy Paws, for grounding, we use a 18"x 5/8" mast top aluminum spike connected through the mast and heavy copper wire to a 10'x2"x1/4" copper grounding bar mounted underwater on the hull. The three radios and the tuner all have quick disconnects, but I still have coax grounds to install. We use the oven and microwave as faraday cages for computers/electronics that are out but not permanently installed, and metalized shielding bags for all stored electrical/electronic equipment. So far no problems; I hope it stays that way.

The idea for the copper bar lightning ground came from the ABYC rules for boat lightning protection. Here is a link with a good discussion of lightning protection systems and the ABYC rules from a custom yacht designer dated 2007-09: www.kastenmarine.com/Lightning.htm

Here's what he says (comparing a

12' strip to a 1 sf plate):

"The ABYC suggests the use of a grounding strip, rather than a plate. The

ABYC rule states: 'A grounding strip shall have a minimum thickness of 3/ 16

inch (5 mm), and a minimum width of 3/4 inch (19 mm).' A strip

approximately one inch (25 mm) wide and 12 feet long (3.7 m) has nearly six

times the amount of edge area exposed to the water, which will improve the

dissipation of charges. 'The grounding strip, if used, shall extend from a

point directly below the lightning protection mast, toward the aft end of

the boat, where a direct connection can be made to the boat's engine'.

A grounding plate, if used instead, should be solid, rather than the

sintered bronze type often used as radio grounds. The sponge-like structure

of the sintered bronze plates may, in the event of a strike, allow the

instant formation of steam, which could blow the plate apart, resulting in

possible severe damage to the surrounding hull".

If you have a 4"x6" grounding plate, like a Dynaplate, or similar,

it is meant for use with an insulated backstay and an automatic antenna tuner--to

provide a connection to seawater as a ground plane (not ground) for an HF

radio. As indicated above it should NOT be used as a lightning ground.

My copper bar is thru bolted to the hull on the port side running from about

the forward main cabin bulkhead aft into the engine room. It took me some

time to get the bolt spacing right so I could access them from inside the

boat and not run them into a floor stringer. Two of the 3/8" bolts are

nearly even with the mast so that I could get short runs of 2/0 wire to each

from the mast without much bend. The connections need to be really solid,

so I did the mast thru bolted connections while the mast was out of the boat

12 years ago.

I think the info you often see in lightning literature referring to a plate

is old, and the bar recommendation is more recent. Several universities,

including Florida and Illinois, and others, including NOAA and ABYC, have

done a great deal of recent research on this subject. It is worthwhile

knowing the source and date of info you read, as the recommendations are

changing as new info becomes available. If you Google boat lightning

grounds/protection you will find much more info on this, including this

useful tidbit on Kasten's site:

"The top-most end, or air terminal, should be a sharply pointed spike.

Alternately, a wire 'brush' type terminal can be placed at the masthead,

with the bristles pointed upward. There are several claims that a single

spike is more effective than a brush for dissipating the charge built up by

the boat".

My spike is 5/8" aluminum, about 18" long. I threaded the bottom so I could

bolt it through a web in the mast cap. I also have a short 6" spike I used

when in the Fla Keys running under the 65' bridges. We have the 18" one on

now that we have no bridges to go under.

Of all the scary things about cruising and boat ownership, lightning scares me the most. Not only because of the potential for huge repair expenses, but also because of the very real threat of loss of life. It is a serious subject worth careful consideration by anyone using a boat.

For a really good article on the differences between the lightning ground, the radio ground, and the electrical ground, see Stan Honey's great article on Marine Grounding Systems (pdf file).

|

Copper bar 10'X2"X1/4" |

|

External Sea Strainers

At the advice of several

lobster fishermen in the Keys I got rid of internal basket sea strainers

11 years ago and installed an external screen filter. There are several

types, but all have a removable heavy screen plate with small holes to

allow water, but nothing else of any size, to pass through. The Keys

are terrible for grass getting into standard strainers, and was a real

pain for me to have to dump it often while doing Boy Scout charters

there my first year. Since I changed to the external screen, I have

never seen grass or anything else in my raw water system, and I do check

it periodically.

It might not be a good solution if you have one of those racing CSYs,

but it sure eases my cruising workload. It really is a great help

in screening out floating junk. Anything that it doesn't screen out

will be so small that it will go all the way through your raw water

system without causing a problem (except sand).

They come in several sizes and the biggest fits over both my engine raw

water and refrigeration cooling water thru hulls. So your thru hull

spacing is like mine you may only need one for the two most important

intakes on the boat. The one you want is rectangular, has a slide out

screen plate, and one end is higher than the other.

I bought mine years ago from Lewis Marine in Ft Lauderdale and recently

bought a new screen from them. Here's the source for external raw water

strainers with removable screens: Lewis Marine, Ft Lauderdale, Fl, fig

6826-Hull Intake Strainers w/ Slide Out Removable Screens, Part Nos

2349-2352, spare screens available, Mfg Tournament Marine Products by

Buck Algonquin

Sen-Dure makes one without a removable screen and Groco makes one with

an opening front door and SS screen. I like the Buck Algonquin one

best. They are not cheap but they sure do work well, and you really

only need one to cover the engine and refrig raw water intakes. I am

using round strainers, fig 8561 over the commode and galley SW intakes.

Prop

Guard, Line Cutter, Rudder Guard

While operating in the Florida Keys during lobster

season, fouling trap lines in the unprotected prop is a constant problem.

Dave and Jim Dill of Chilly Pepper designed this fin guard for the

prop after considerable thought and consultation with the commercial

lobstermen. It is heavy enough to handle almost any line but

will still break away without damaging the hull in a heavy grounding.

It is constructed of a 1/2" foam core with one layer of fiberglass cloth on

each side and another layer around the edges. It is firmly

bedded in an epoxy trench cut into the keel stub and then faired with epoxy

and cavasil additive. It does a good job and guides about 75

percent of the trap lines under and away from the prop.

I have also installed a fiberglass tab between the aft end of the skeg and

the forward end of the rudder to prevent a line from getting up into the gap

between them. It is fastened only to the bottom of the skeg with 3

small SS screws. And finally I have installed a line cutter on the

shaft just forward of the prop.

The photos below show the new shaft as it was originally installed in 2005,

with about 10" between the aft end of the cutlass bearing and the forward

end of the prop. Within two years I had to redo the installation

because the extended length of the shaft wallowed out the cutlass bearing as

the prop whipped around. The correct distance should be no more than 4

times the shaft diameter or 6" max. I cut the shaft to allow about 5",

just enough room for the line cutter and the zinc. Now two years later

all is well.

|

|

|

|

Fiberglass tab between skeg and rudder to prevent line fouling |

Line cutter with plastic guard on |

|

|

Blister Repair and Barrier Coat

Though the CSYs were constructed before the major issues with underwater blistering occurred (mid-80's, due to a change in the resin), we had experienced a good number of small blisters over the years. We had already done a complete "blister repair" once, using West System epoxy as the barrier coat, but were still seeing blisters in the underwater hull. (It turns out that West Epoxy is so thin, that it is not a very good barrier epoxy unless you put ~20 coats on).

So, while in Ecuador in 2009, with low labor rates, we hauled out, and under the guidance of an expert (George Stewart), did a major blister repair, barrier coat, and bottom job.

We used the Hempel paint system, because that was what was available easily in Ecuador, and also what a friend had used several years before. Here is what we used (prices are in Ecuador, in USD). The Hempel Mastic/Coal Tar Epoxy/Chlorinated Rubber makes a nice thick barrier coat--better than West System, which is a thin epoxy and takes many coats to make an effective barrier coat. Unfortunately, Hempel doesn't really market/sell to yachts in the U.S.

| s/v Soggy Paws Sq Feet: | 578 | 31-August-2009 | |||||||

| Product Name | H# | Colors | # of Coats | SqFt Covg per US Gal | Total Gallons Needed | Total Liters Needed | Liters to Order | Quoted Cost Per Liter | Total Cost |

| Low Vis Epoxy Primer | H15300 | Red / Gray | 2 | 511 | 2.3 | 8.6 | $8.96 | ||

| Base 15309 - Red | 15309 | 50890 | 1 | 1.1 | 4.3 | 10 | $89.55 | ||

| Base 15309 - Gray | 15309 | 12170 | 1 | 1.1 | 4.3 | 10 | $89.55 | ||

| Cure 95040 | 95040 | 2 | 0.5 | 1.7 | |||||

| Thinner 08450 | 8450 | - | 0.1 | 0.4 | |||||

| Mastic | H45880 | Gray | 2 | 154 | 7.5 | 28.4 | 35 | $11.40 | $399.06 |

| Base 45889 - Gray | 45881 | 11480 | 2 | ||||||

| Cure 95880 | 95880 | 2 | 1.9 | 7.1 | |||||

| Thinner 08450 | 8450 | - | 0.4 | 1.4 | |||||

| Coal Tar Epoxy | H35670 | Black | 2 | 185 | 6.2 | 23.7 | 40 | $8.73 | $349.29 |

| Base 35670 - Black | 35670 | 19990 | 1 | 3.1 | 11.8 | ||||

| Cure 98670 | 98670 | 2 | 1.2 | 4.7 | |||||

| Thinner 08450 | 8450 | - | 0.9 | 3.5 | |||||

| Thinner 08450 Total | 8450 | 1.4 | 5.4 | 8 | $6.66 | $53.28 | |||

| Hi Build Chlorinated Rubber | H46330 | Grey | 1 | 211 | 2.7 | 10.4 | 15 | $8.98 | $134.73 |

| 1 Part - Grey | 46330 | 11480 | |||||||

| Thinner 08080 | 8080 | 0.1 | |||||||

| Globic AF | H8190M | Red/Blu/Blk | 4 | 209 | 11.1 | 41.9 | $28.05 | ||

| Color Red | 8190M | 58000 | 2 | 5.5 | 20.9 | 25 | $701.34 | ||

| Color Black | 8190M | 37000? | 2 | 5.5 | 20.9 | 25 | $701.34 | ||

| Thinner 08080 | 8080 | 0.6 | 2.1 | ||||||

| Thinner 08080 Total | 8080 | 0.7 | 2.6 | 4 | $5.61 | $22.44 | |||

| Laquer Thinner | 3.0 | 11.4 | 10 | ||||||

| Subtotal | $2,540.59 | ||||||||

| Liters per Gal | 3.785 | Delivery | $25.00 | ||||||

| Gals per Liter | 0.264 | Subtotal | $2,565.59 | ||||||

| IVA 12% | $304.87 | ||||||||

| Download Spreadsheet | TOTAL | $2,870.46 | |||||||

First, we had George's guys use 8" rotary sanders with 36 Grit sandpaper, to sand down to bare fiberglass (including the old barrier coats). Then we tested the moisture level in the hull, in about 75 spots on the hull, and recorded the readings in pencil (with the date) on the hull.

Once the bottom was down to bare, smooth fiberglass, we carefully looked over the hull for blisters. At this point, they are usually weeping moisture. Every blister we saw, we circled in magic marker (as they dry out, they get harder to find). Then the guys carefully took a small grinding tool, and ground out each of the blister spots. For the next few weeks, we washed down all the blisters with fresh water a couple of times a day. This rinses/drains the chemicals left over in the fiberglass that caused the blisters initially.

We let the bare hull dry out for almost 6 months, while we were otherwise occupied with touring in South America. As it was drying, we did periodic moisture testing (monthly at first). After a few months, we repeated the moisture testing weekly--focusing on the "still too wet" spots.

|

|

Once the hull was sufficiently dry (the length of time this takes depends a lot on how wet it is to start, and the humidity level where you are drying out), we started the rebuilding process:

First, all the blisters we ground out had to be filled with filler and faired. Then we built the bottom coating back up in this order:

2 coats of Low Viscosity

Epoxy Primer H15309-A thin 2-part epoxy that flows easily and provides a

great bond to the bare fiberglass.

2 coats of Mastic H45881-A very hard and thick epoxy.

2 coats of Coal Tar Epoxy H35670-A thick epoxy with lots of solids.

1 coat of Chlorinated Rubber H46330-A 'tie coat' that allows application of

bottom paint after the epoxies dry.

4 coats of Hempel Globic Bottom Paint H8190M-An ablative copper based bottom

paint (two coats each in 2 colors with lots more coats around the water line

and leading edges).

Thickness of the resulting barrier coat is over 40 mils.

There are some pretty specific drying and re-coating times in the transition between the Mastic, the Coal Tar Epoxy, and the Chlorinated Rubber. (I don't remember the details, but in one case, one layer had to be applied in a very specific time window, to properly bond and make a tie coat for the bottom paint). Carefully read the Hempel literature, and/or ask your dealer for guidance.

2013 Update: It has been 4 years since we did this, and still not a single blister has come back (unlike the first 2 times I did "blister repair jobs".)

The Hempel bottom paint we originally applied in 2009, and refreshed with an additional coat in our haulout in Hawaii in 2011, had done a good job, but was starting to get thin--we could see the red 'warning coat' starting to show through in quite a few places. And we were getting more growth (however, the growth still removed easily--was mainly soft stuff--virtually no barnacles or clamshells.

So in Feb 2013, unable to get Hempel paint in Fiji, we applied "Blue Water Marine Copper Shield 45" paint (shipped in from U.S.). Practical Sailor gave it a good review as a Budget Buy in their Bottom Paint tests--it was the only inexpensive ablative that lasted pretty well after 24 months. We'll let you know how it holds up in the warm waters of the western Pacific.

How We Calculated the Underwater Square Footage of Soggy Paws

After first asking other

CSY owners, and getting no reply. I calculated the underwater hull

square footage on our CSY 44 shallow draft myself.

The procedure is as follows:

-

Using a flexible tape measure, start at the bow and make a mark along the water line every three feet moving aft along one side of the boat. For us 13 marks.

-

Then measure down, perpendicular to the waterline, along the hull to the centerline of the bottom at each 3' station. Record these measurements and the water line mark they came from.

-

Aft, at the beginning of the rudder skeg, where the hull is not uniform, use the tape measure to individually get a close estimate of the rudder, skeg and stern square footage. These total about 25 sf each side.

-

Lay out the 3' marks along the top of a piece of graph paper with one square equalling one square foot. Drop perpendicular lines down from each mark corresponding to your measurments.

-

Connect the bottom ends of the vertical lines. This curved line will correspond to the bottom centerline of the boat.

-

Count the squares and portions of squares. Each square is one square foot. Add the estimates for the rudder, skeg and stern. Double the total so you include both sides of the boat.

-

Our total was 577 square feet with our waterline raised up about 4". I think the accuracy is within 5 square feet. Note, this is for a SHOAL Draft (5' draft) CSY 44.

Obviously, it is a lot easier to do this with the boat out of the water.

The centerline of the forward strap should be about 1/2 of the distance from the forward lower chainplate to the aft fixed porthole in the hull (the aft porthole of the 2 portholes in the bow).

The forward edge of the aft strap should be just on the aft edge of the

first porthole aft of the steps.

Do NOT put the aft strap between the prop and the rudder skeg, because there

is too much sag in the middle of the boat.

Do NOT put it just forward of the prop, behind the keel, because that area

is not strong enough, and might crush or crack the prop shaft stern tube.

Some additional pictures from our haulout in Hawaii in 2011:

Mounting Emergency Depth Transducer While In the Water

When our old depth sounder failed as we were getting ready to cross the Pacific, we grabbed an inexpensive "fishfinder" out of our projects box and mounted it INSIDE on our big boat, without cutting a hole in the hull.

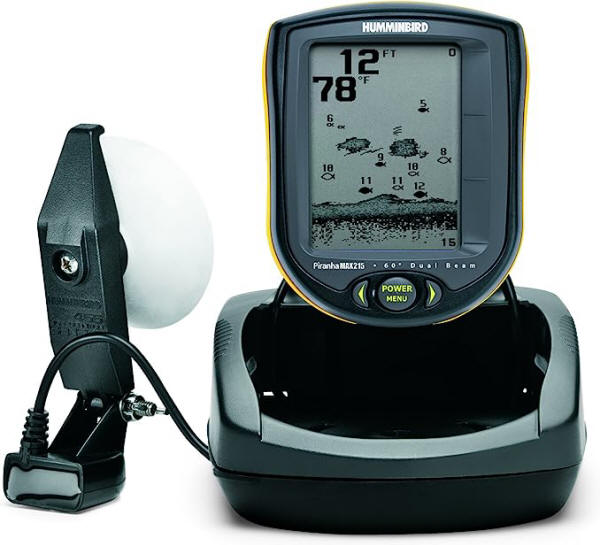

The unit was a Huminbird Piranhamax 215 that cost us $89 on sale at West Marine in 2009. We bought it for our dinghy, but never got around to installing it, before our big boat sounder died.

It is what it looks like..A low-end fishfinder with transom mount

sounder. If you want color, add another $50-100. We bought a color one a few

years later, as it helps to show you the texture of the bottom.

To

mount, we used the standard transducer that came in the box, included with

the fishfinder.

We mounted ours in a place where it would go through

solid fiberglass about 1" thick. If your hull is cored, or plywood, it may

or may not work as well as ours does. Ours works to about 300 feet. It also

works well enough through the hull in anchoring depths to be able to see the

bottom profile and get an idea of what's down there (mud, grass, rock,

sand).

We tested it before sticking it down by pressing the bottom of

the transducer right on the inside of the hull where I wanted to mount it,

and see if we got reasonable readings.

The instructions suggested

that it would not work with silicone because of bubbles, and others said to

mount it in epoxy. But I didn't want such a permanent mount--this was only

temporary (5 years ago--ha!). So I used 3M Marine silicone.

I picked

a spot in my engine room (the location where we could reach with the cord

through the porthole in the cockpit). I dry fitted it in the location I

selected, and tested it to make sure it was reading OK. Then I put a big

glob of silicone in the appropriate location and pressed it down hard onto

the hull into the silicone, as level as possible to the bottom. I did mount

it on a portion of the hull that wasn't flat to the bottom, so I levelled it

a little by using a pretty big glob of silicone. But just be careful of

introducing bubbles.

Ours is mounted about 3 feet off centerline and

has about 10-12 degree tilt, outward from the center of the boat. Which, in

the grand scheme of things, isn't much in error, considering we had no depth

sounder at all to start with.

I don't think the cheapie Humminbird has an offset correction, so it is reading conservatively (like 2' less than what's actually there, because it's location on the hull, 2' below the waterline), so a 6" to 1" error caused by the 10 degree tilt isn't much.

We kept this arrangement until we sold the boat in 2015...and have a similar arrangement on our catamaran. We much prefer a fishfinder to a standard depth sounder, as it shows you a lot about the bottom contour as you try to pick a good anchor spot.